Systems Engineering

Mechanical and electrotechnological systems used in homes and industry have significant effects on society and the environment. VCE Systems Engineering students apply innovative thinking and problem-solving skills to technologies in ways that transform people’s lives.

Students design, construct and assemble an integrated and controlled aspect of an operational system using mechanical and electrotechnological components. They solve a system-based problem, need, opportunity or situation by applying technological, mathematical and scientific principles. Production activities are planned and recorded, before they are tested and evaluated. Systems on display reflect creative thinking and technical skills.

Christopher Batras

Penola Catholic College, Broadmeadows

Bunurong Boonwurrung Country

ALMMPA, Affordable Lightweight Multiarticulate Myoelectric Prosthetic Arm

SURFACE ELECTROMYOGRAPHY SENSOR, MICRO SERVO MOTORS, ARDUINO MICROCONTROLLER, RGB LED, RESISTORS, WIRES, LITHIUM BATTERY, FISHING LINE, ELASTIC THREAD, METAL SCREWS, 3D PRINTED MODIFIED INMOOV POLYLACTIC ACID PLUS COMPONENTS: NUTS, BOLTS, ARM, SERVO ADAPTOR AND SPUR GEARS

Designed for accessibility, ALMMPA blends affordability with advanced functionality. Controlled by a muscle electromyography sensor, the prosthetic arm features five micro servo motors connected to fishing line and elastic thread that act as artificial tendons for finger articulation. The Arduino microcontroller interprets elevated voltage signals from the sensor when the amputee contracts their muscle, enabling seven distinct grip modes with synchronized RGB LED colour changes to reflect the active mode. This innovative integration of technology and biomechanics is dedicated to significantly improving the quality of life for amputees.

Louie Dodds

Kardinia International College, Bell Post Hill

Wadawurrung Wathaurong Country

Hydroelectric Dam

Acrylic, silicon, electronic relays, switches, capacitors, resistors, LDRs, solar panels, diodes, LEDs, terminal blocks, 6V batteries, plywood, pine wood, screws, nails, glue, steel mount, rubber furniture grippers, PLA plastic, plaster of Paris, artificial trees and rocks

I have produced a scale model of a hydroelectric dam that generates electricity using an input of water via an intake chute. The system uses an Arduino board and closed loop system to control an artificial reservoir's water level and penstock subsystems, then directs the generated electricity to LED outputs. A storage container catches the water as it runs through the dam, which is then actively pumped back up to continually produce a constant DC voltage output, satisfying the design brief.

Manuel Fay

Parade College, Bundoora

Wurundjeri Country

Train Colour Sorter System

Arduino Mega board, servo switches, stepper motors, stepper motor driver, 3D printed PLA components, 19V DC power supply, infrared sensors, GY-31 colour sensor, L298N motor module, 12V-5V DC converter, 00 model train gauge track

I have designed a system to sort trains by colour through a variety of functional techniques such as rotation, sliding, and pivoting. The device identifies trains placed on the system and individually guides each one towards the colour sensor. This sensor detects the train's colour and determines the appropriate track. The system then propels the train onto the correct track. Once all trains have reached their final positions, the system powers down.

Jeremy Gray

Scotch College, Hawthorn

Wurundjeri Country

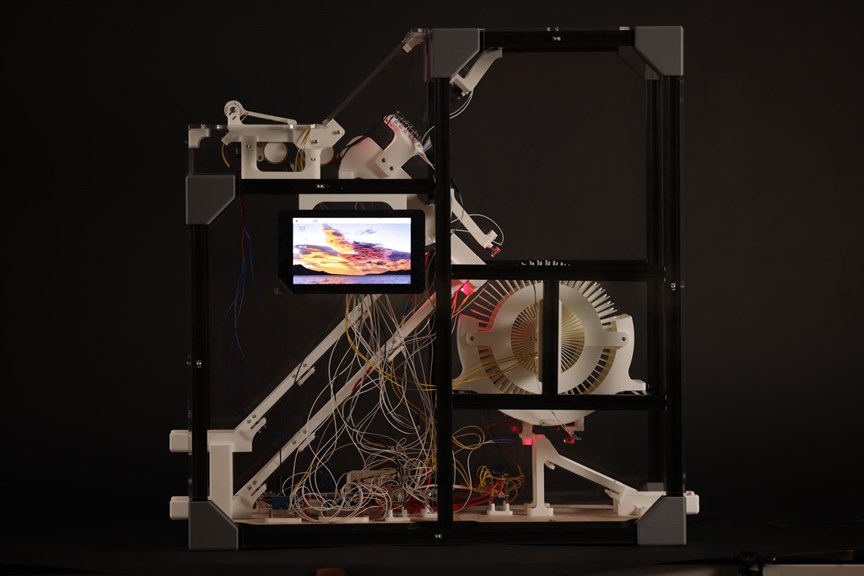

Magnus Effect Wind Turbine

Arduino Uno, Adafruit Motor Shield V2, DC motors, servo motors, stepper motor, potentiometers, bearings, gears, LCD screen, alkaline batteries, 3D printed PLA components, aluminium tube, slip rings, steel frame

I have built a wind turbine that utilises the Magnus Effect instead of using traditional airfoils. The Magnus Effect is a feature of airflow around a spinning body that is also moving in relation to the airstream. Using an Arduino Uno microcontroller, this approach gives a lot more control to the operator over how much lift is generated and allows the turbine to operate in a wider variety of wind conditions. My design demonstrates how this type of turbine can be used in areas where wind speed and direction are widely variable, such as urban environments.

Jamie Phelps

Belmont High School, Belmont

Wadawurrung Wathaurong Country

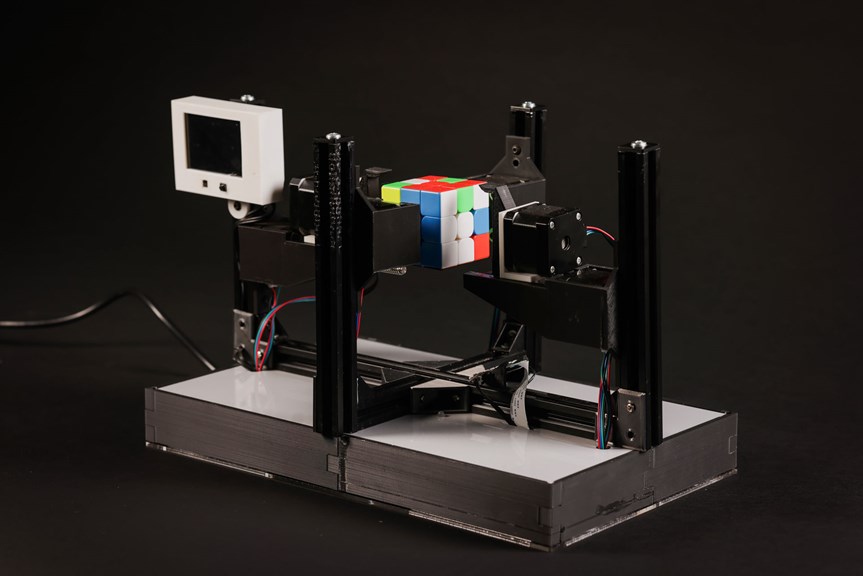

Rubik’s Cube Solver

Raspberry Pi 3B+, Arduino Uno, Arduino Uno LCD display shield, A4988 stepper motor drivers, NEMA 17 stepper motors, Pi camera module, lead screws, PLA 3D printed components, laser cut acrylic components, push button, Aluminium v-slot strut, Rubik’s cube, Molex power connector

I have created a system that automatically solves Rubik’s Cubes. It uses a camera and a specifically designed colour detection algorithm to accurately read the Rubik’s Cube state. The system then uses the Kociemba solving algorithm to generate a sequence of actions to the solved state, then executes these actions efficiently, solving the Rubik’s Cube. The time taken to read and solve the Rubik’s Cube is shown on the display.

Justin Pollock

Padua College, Mornington

Bunurong Boonwurrung Country

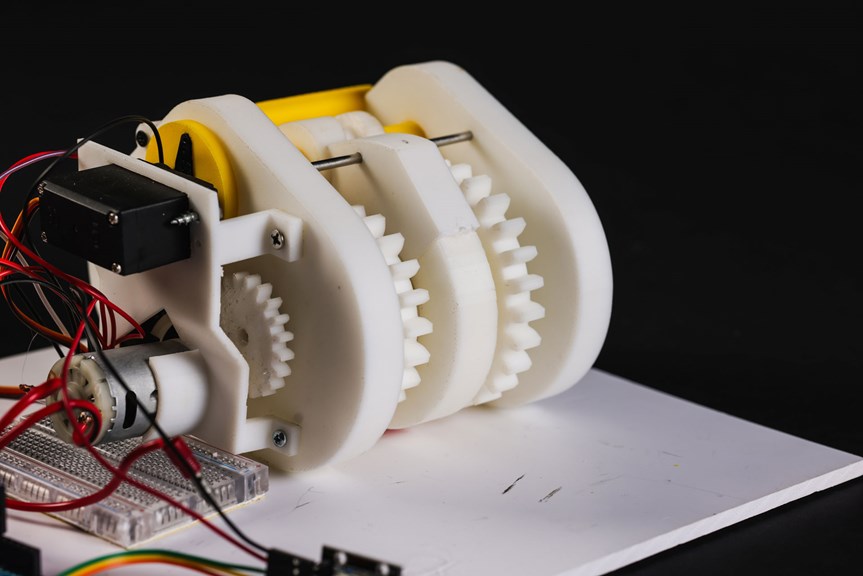

Automatic Transmission

DC electric motor, Arduino Uno, hoto interrupter, rotary encoder, LiPo battery, digital servo motor, DC battery, Bread board, PLA plastic 3D printed components, 15 gauge wire, bearings, washers and bolts, metal axle, jumper cables

I have created a system that can change the ratio of torque and speed from an input to an output. Running on an Arduino Uno, the transmission can change gears automatically using a servo motor depending on the measured Revolutions Per Minute (RPM) of the system. The motor speed can be manually controlled by the operator to simulate the different scenarios that the transmission can be used in.

Haisong Qi

North Geelong Secondary College, North Geelong

Wadawurrung Wathaurong Country

Automatic Card Sorter

Raspberry Pi 4B, SparkFun RedBoard Plus, touchscreen, MCP3008 ADC, magnet, TLV493D magnetometer, L298N motor driver, S13V30F5 voltage regulator, relay, BC547 transistor, resistor, LED, laser diode, LDR, DC motor, servo motor, stepper motor, stepper driver, 18650 battery, GT2 timing belt, 2020 aluminium extrusion, T-nut, bearing, smooth rod, PLA, ABS, plywood, acrylic

I have developed a device that sorts playing cards into order using three electromechanical subsystems. Cards are first dispensed one at a time using friction feed. A camera then captures an image of each card and the system recognises it using a deep learning algorithm powered by a convolutional neural network. Finally, a rotating drum is used to arrange the cards in the order defined by the program. This device is operated via a graphical user interface on a touchscreen.

Clancy Wilson

Scotch College, Hawthorn

Wurundjeri Country

Automatic Truck Unloader

Arduino Uno, DC motors, servo motor, 9V batteries, wheels, motor driver shield, RIFD reader, line sensors, PLA 3D printed components, screws, wires

I have designed a system that automates loading and unloading pallets from the back of a semi-truck. The system would be based in a warehouse to unload pallets from a truck and deliver them to a designated place. The scale model system is controlled by an Arduino and navigates through the use of a RFID reader and two line sensors. Through this automation, the Automatic Truck Unloader attempts to reduce forklift related accidents in the workplace.