Products

‘It’s made by Kodak, so you know it’s good.’

From the manufacturing of photographic plates and paper products by Thomas Baker in the 1880s right through to the production of specialised film products for international export in the 1990s, Kodak Australasia holds a special place in Australia’s manufacturing and cultural history, and – alongside Kodak Limited (England), Eastman Kodak (United States) and Kodak Canada – was a significant force behind Kodak’s global brand.

As well as importing and selling goods from Kodak subsidiaries around the world, Kodak Australasia manufactured and distributed millions of photographic products to Australia and the Asia-Pacific region, such as film, paper, chemicals, cameras and miscellaneous equipment. With almost 100 years of onshore manufacturing via its Abbotsford, Burnley and Coburg factory sites, Kodak Australasia’s products were strongly geared towards amateur and professional consumers, but also included specialist medical, business, industrial, motion picture and graphic art professionals who used photography, x-ray and other imaging techniques.

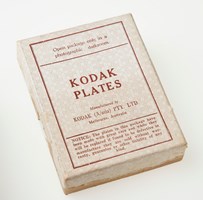

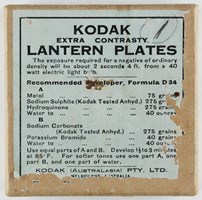

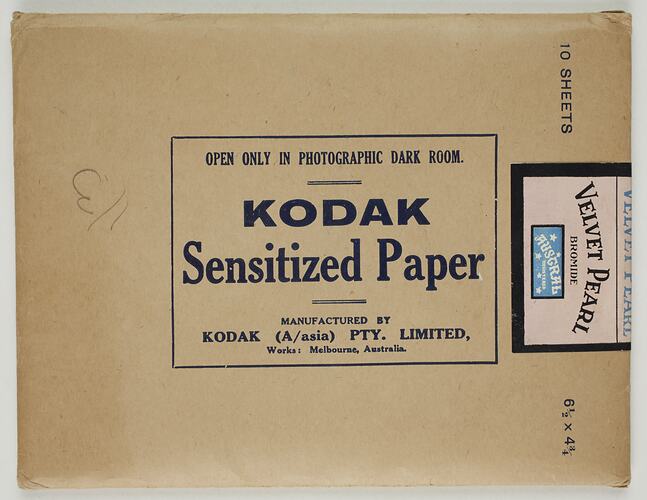

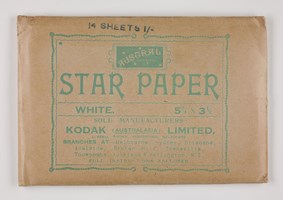

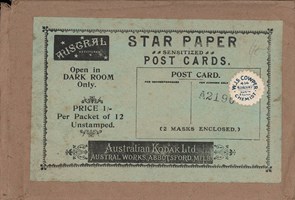

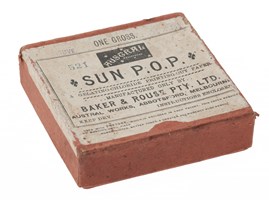

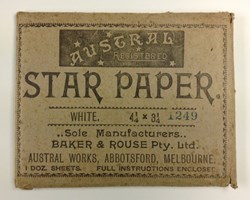

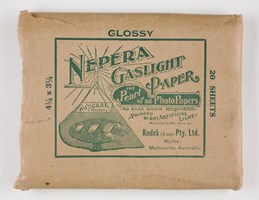

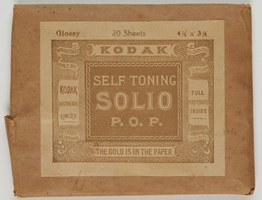

Kodak Australasia’s manufacturing history is deeply grounded in the production of photographic paper. Beginning with the early days of Baker & Rouse in the late 1800s, the photographic paper industry was undergoing a significant period of change both internationally, and in the Australian colonies. For the most part of the 19th century albumen paper had dominated commercial studios worldwide, however changing technologies were emerging in the late 1880s and Baker and Rouse were at the forefront of these new trends. In 1887, the Abbotsford factory began producing a new bromide paper, known as ‘Austral Pearl Bromide’, which replaced albumen paper. In 1894, a new gelatine chloride Printing Out Paper (POP) was introduced under the name ‘Austral Sun’, and by the 1900s the factory was in full swing producing a wide range of bromide and gaslight papers, negative materials, mounts, envelopes, and ready mixed chemicals.

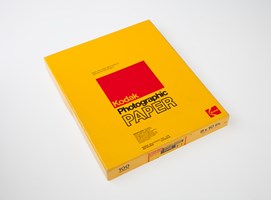

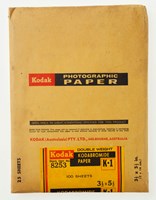

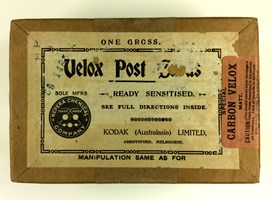

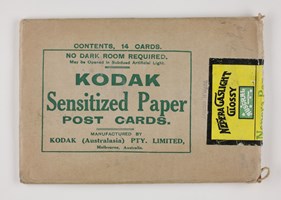

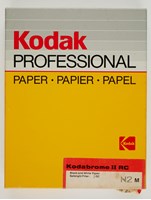

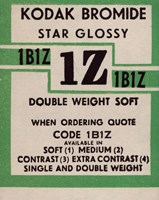

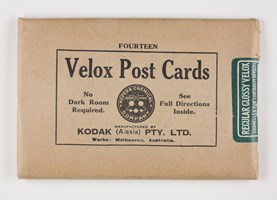

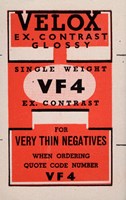

Moving into the early 20th century, Kodak Australasia continued to produce a wide range of paper products, including Printing Out Paper (POP), self-toning paper, post cards, photo printing paper and Velox paper – ‘the special paper made by Kodak.’ At the Coburg factory, which opened in 1961, Ektacolor Paper was in production right through the 1960s until the last paper coating run in November 2004.

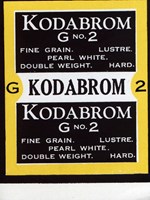

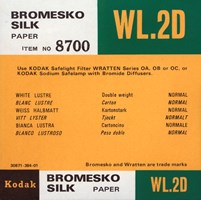

All of Kodak's papers came with instructions about what light conditions the paper could be opened in, and whether or not a dark room would be required, and were packaged with warning labels such as ‘only open under light conditions specified for this product.’ As paper manufacturing technologies evolved throughout the 20th century, Kodak Australasia’s paper range expanded to include a wide range of styles including glossy, matte, silk, velvet, fine grain, double weight, soft and extra contrast. Paper packaging designs and labels also became more colourful over the years, reflecting the shift to a wider range of colour printing options.

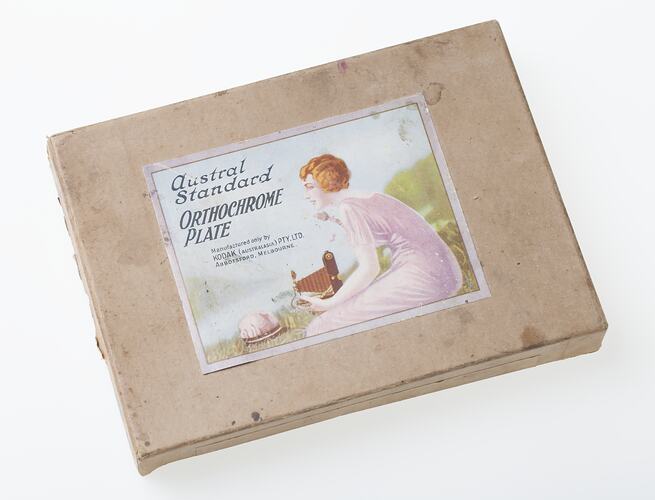

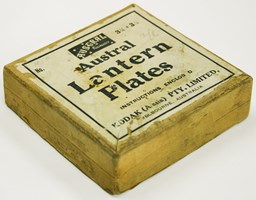

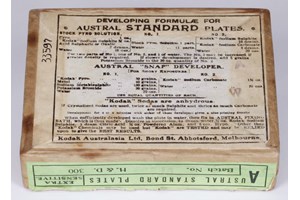

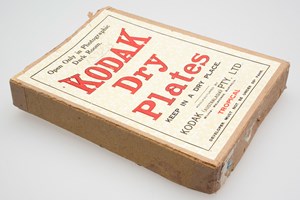

Paper Gallery, 1890s-1950s

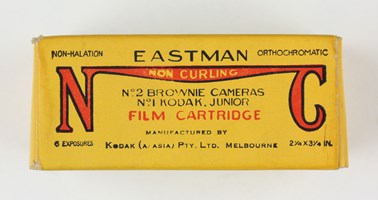

Soon after Baker and Rouse merged with Kodak Limited to form Kodak Australasia in 1908, film products began to be manufactured on the banks of the Yarra River in Abbotsford, Melbourne. Production began with “Eastman Non Curling” film, which was manufactured using the same methods as Eastman film products sold in the United States. Eastman had introduced non-curling film (NC film) for amateur cameras in 1903, heralding a shift away from dry plate technologies to cellulose nitrate roll-film. Kodak Australasia’s non-curling film remained a popular choice for many decades and was manufactured in a number of formats to suit different Kodak cameras.

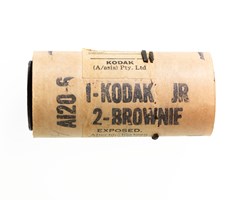

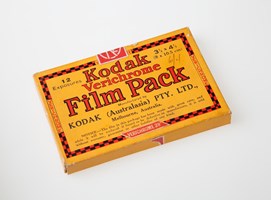

In 1931, Eastman Kodak released “Verichrome Safety film” on a safety base as roll film, and Kodak Australasia soon began manufacturing this film locally via its Abbotsford factory. Produced in roll-film and film-packs, Verichrome film became a highly popular material due to its wide exposure latitude and finer grain than Non Curling film. In 1956, Verichrome Safety film was replaced with Verichrome Panchromatic (Pan) film, which offered an even finer grain and remained in production for several decades.

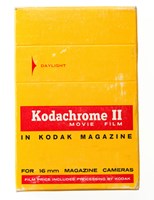

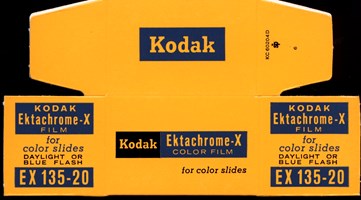

Kodak began to offer colour film options as early as the 1930s via its Kodachrome film series, which was released in the United States in 1935 as the first colour reversal (slide) film for use in both cinematography and still photography. Kodachrome processing started at the Kodak factory in Abbotsford in 1936 after Kodak Australasia staff Dr Neil Lewis and Mr Jack Monteith visited Kodak in Rochester, New York, to establish the requirements for setting up the facility. A purpose-built four story “Kodachrome Building” was established to manufacture Kodachrome 35mm slide, 16mm and 8mm movie films. It remained in operation until the 1960s when the plant moved to Coburg.

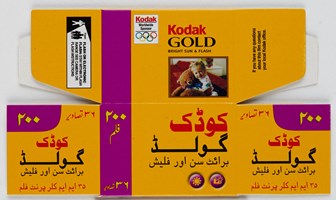

Moving into the 1950s and beyond, Kodak Australasia also produced colour negative film via its Kodacolor division in Coburg. Kodacolor negative film was produced in a number of formats and iterations, including the popular Kodacolor-X for instamatic camera use in the 1960s-1970s and Kodacolor Gold (100, 200 and 400) in the 1980s-1990s. A purpose-built Color Laboratory operated at the Coburg factory to process Kodacolor, as well as Ecktachrome film, and in 1968 a new Kodak Color Laboratory opened in Sydney to service the New South Wales and Queensland regions.

During the 1980s right up until the Coburg factory ceased operations in 2004, a significant proportion of Kodak’s film produced in Australia was exported to the Asia-Pacific region. Film was packaged in multiple languages, with designs emphasising that the film was “Made in Australia” and celebrating major international events such as the Seoul Olympics in 1988.

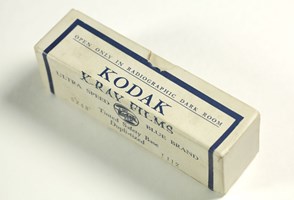

As well as manufacturing film for professional and amateur photographers and movie makers, Kodak Australasia also produced a wide range of film for other purposes over the decades, including graphic arts film, photomechanical film, aerographic film, X-Ray film, microfilm and ortho printing film.

Film packaging also evolved over the years, with film canisters making the switch from metal to plastic, and cardboard box designs changing over time in line with international trends.

Film Gallery, 1890s-2000s

Baker & Rouse began making cameras in the 1880s and 1890s, and sold these cameras their through their Baker & Rouse retail outlets. They also imported and sold cameras from a range of overseas manufacturers.

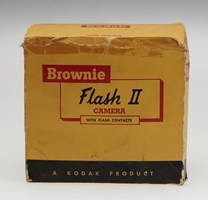

Many decades later, Kodak Australasia began assembling cameras in Australia at the company's Abbotsford factory in 1957. The first camera to be assembled locally was the Kodak Brownie Flash II. This model camera was originally designed and built by Kodak Limited, England, and the parts for Australian assembled products were imported from England.

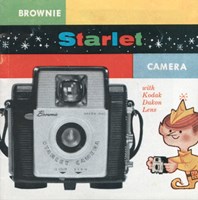

From 1958 an increasing range of components was made locally, and soon the Brownie Flash II was replaced by the Brownie Star series of cameras, which were assembled from more than 95% Australian parts. There were three camera models in the Star series, and ten million of them were sold around the world in five years. The first Star series product locally assembled was the Brownie Starlet camera, which was originally created by Eastman Kodak in the USA in the late 1950s. This was followed by the Brownie Starmite and then the Brownie Starflash, the latter being the first Kodak camera with a built-in flash holder.

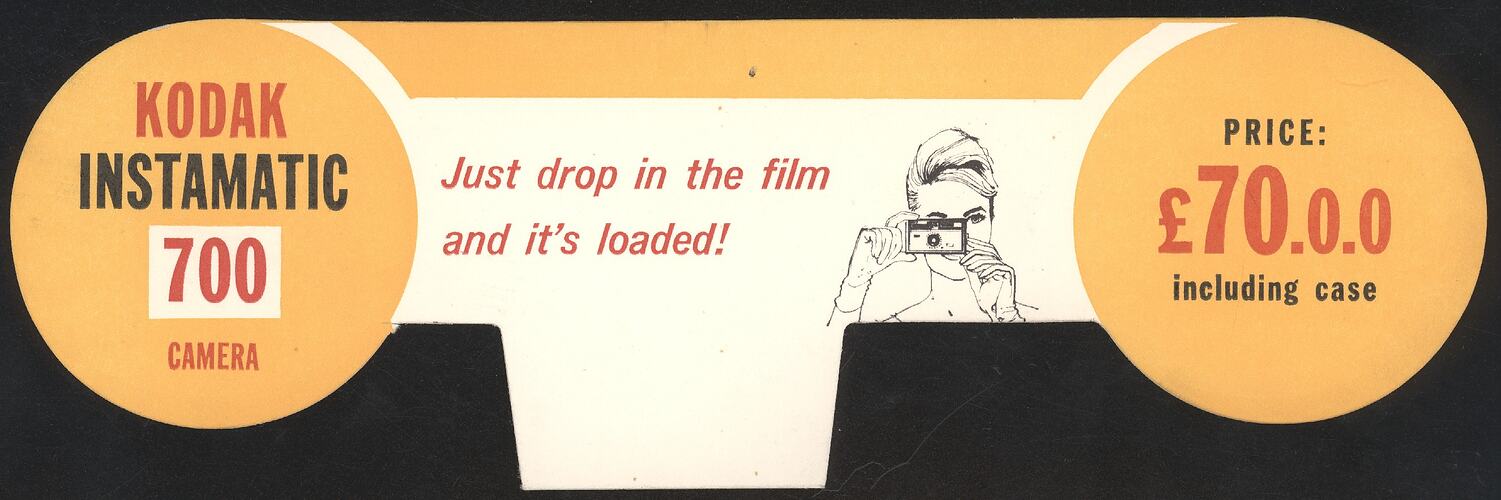

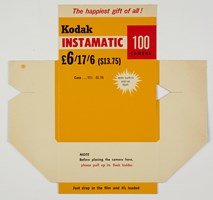

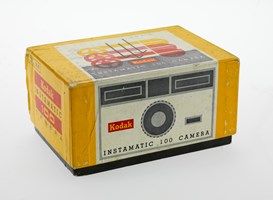

In 1963 Kodak Australasia began production of lnstamatic cameras in the Camera, Reels & Sundries Department in Building 15 at the company's new factory in Coburg. The small and compact Instamatics had a huge impact on amateur photography, as they were inexpensive, easy to use and loading the camera with film was fast and easy – users only had to drop a film cartridge (126 format) into the back of the camera. The first Instamatics to be assembled locally in Australia were models 50, 100 and 104. By 1970, 50 million Instamatics had been made worldwide.

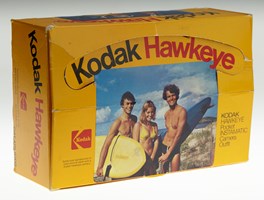

In early 1974, Kodak Pocket Instamatic cameras went into production at Coburg. The Pocket Instamatic model 92 began production in 1977 and in the same year, the X-Series Instamatic model also began to be assembled at Coburg, including the 56-X, 76-X, 177-X and 277 models. By 1981, however, the production of cameras in Australia ceased, largely due to the competition from international manufacturing plants. However, in the twenty-four years that the Camera, Reel and Sundries Department was assembling and making cameras at the Abbotsford and Coburg factories, it had successfully produced over four million cameras.

Camera Gallery, 1950s-1980s

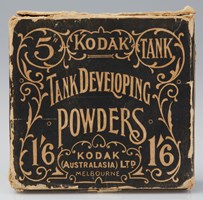

Kodak and its predecessor companies made and imported a very wide range of photographic chemicals. It catered for both the home darkroom enthusiast who wanted to develop and print their own photographs, professional photographers who processed large quantities of negatives, as well as the developing and printing laboratories that processed film commercially.

Chemicals were part of the company’s product list from the beginning. It was particularly important for photographers to be able to process their images in the 19th century when there were few commercial processing services available, and Baker and Rouse stocked a wide range of chemicals, including citric acid, glacial acetic, nitric acide, borax, gelatine and magnesium power, among many others.

Once the company was operated as an Australian subsidiary of Kodak, from 1908, the range of chemicals increased. Kodak Australasia had access to the standardised Eastman Kodak formulas for making certain Kodak chemical products, and could import others. From the early 20th century, these chemical products catered not just for amateur and professional photographers, but specialised users such as the graphic arts, business, motion film and health imaging markets.

As colour photography expanded in popularity, Kodak Australasia made, packaged and sold items specifically for processing images like toners, dye transfer chemicals and developing chemicals, including some for home darkrooms – although usually commercial laboratories processed colour photography.

Photographers who developed and printed their own images would have had a cupboard full of photo-chemicals. As tighter occupational health and safety regulations were introduced during the 20th century, many of the photographic chemicals were labelled as poisons with specific handling instructions. Over time most amateur photographers came to rely on their local photo-processing service to print their images, and the use of photographic chemicals at home became a niche hobby.

Kodak Australasia continued to make chemicals for commercial processing for many decades, however, and in the 1980s and 1990s exported some chemical products – such as photochemicals for processing film – to the Asia Pacific region and China.

Chemicals Gallery, 1920s-1980s