Powder, Chemicals and Dance Club

The Burnley Factory, 1950–1974

Operating from 1950–1974, the Burnley factory was a thriving and busy arm of Kodak Australasia’s onshore manufacturing operations, with chemical manufacturing and packaging, as well as black and white photo processing, taking centre stage.

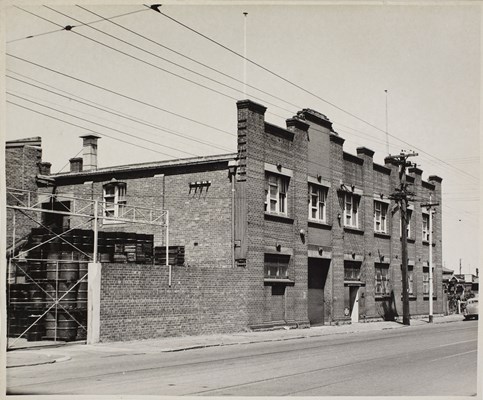

In 1950, at a time of booming product sales and high consumer demand, Kodak Australasia purchased a new factory building at 550-556 Swan Street in Burnley. Previously home to a honey factory, this building would soon house Kodak’s Black and White Photo-Finishing Laboratory (later the Developing and Processing Department), as well as their Powder and Solution Department (later the Photochemical Department).

From Honey to Photo Processing

Opening a new factory had become necessary in the late 1940s-early 1950s because Kodak's original Abbotsford factory had run out of space and was too cramped for the business to expand. Former Black and White Laboratory staff member John Garrett, who worked at the Burnley factory in the 1950s, noted that the company wanted to introduce a same day processing service to compete with other processing laboratories, which required a large-scale extension of Kodak’s processing facilities.

The large brick building in Swan Street was well equipped for a growing manufacturing business, as for many years prior it had been the Barnes Honey factory. John Garrett recalls he was told at the time:

“We've bought (the honey factory) and it's all been repurposed and all fashioned up, all flash now."John Garrett

However, Noel Monteith, who was in charge of insurance at Kodak during this period, recalled that despite being repurposed for Kodak use, Burnley still had wonky wooden floors which were "bad, very bad indeed" and he considered the factory a great fire risk. With hazardous and flammable chemicals a major part of the photo manufacturing operations at Burnley, Kodak plumbers had to install a fire sprinkler system there to protect the building.

Photographs and motion film footage of the period show the facility to be quite basic, with highly manual work equipment installed and the space crowded full of stored materials and product.

Burnley Footage 1960s

The following scenes, captured in the 1960s, give a behind-the-scenes glimpse into the spaces, machinery and working life at the Burnley factory. This footage is thought to have been shot by the Burnley manager at the time, Brian Daniels, and is an extract that was taken from a longer piece of footage. The footage was originally silent, but a musical backing track has been added by the digital team at Museums Victoria.

Working Life at Burnley

Despite the wonky wooden floors and basic facilities, the Burnley building boasted a delivery entrance and yard, and with its multi-story building it could accommodate a large number of staff for its manufacturing, processing, packaging, storage and distribution operations.

The building was also well served by public transport for staff to travel to work. It had a tramline out the front which could bring workers right to the door, and a train line ran behind it with Burnley train station nearby. Swan Street was also a major road link and convenient for those staff who drove there, and for company deliveries.

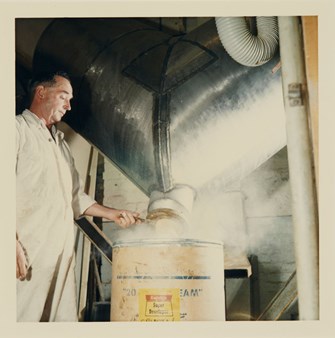

The Burnley factory was a thriving place where workers carried out intensive manual labour. Photo chemicals were manufactured, mixed and packaged in the Powder and Solution Department on the ground floor, while Black and White Photo Finishing was on the first floor. The basement was used for the re-circulation of developer and other chemical solutions for the developing and printing process. Pumps in outbuildings and in the basement helped to move solutions through the system.

In the Powder and Solution Department, staff worked under daylight conditions and staff work roles were largely separated along gender lines. Former staff member Marie McKinley (later Marie De Camara) recalled:

“The men were outside, they were in the annexe part and they were mixing the liquid and the chemicals ready to bring in for us (girls) to do the packing part of it.”Marie De Camara

Staff wore safety glasses and gloves when required and were trained to be very careful handling the chemicals, which could be hazardous. Marie recalled that the women wore aprons, and later on wore a uniform to protect their clothing from the chemicals, and when she moved into quality control she wore a white laboratory coat.

Marie De Camara's Digital Story

In the Black and White Photo Finishing Department, men generally performed the developing work while women undertook the printing. Some of the work was done in darkroom conditions, such as developing the negatives and making enlargements, while other aspects of the work, such as the printing, packaging and administration, was done in daylight.

John Garrett worked in the darkroom quite a bit, developing negatives and processing film via the automated developing machines. He recalled:

“We had a gang of people working there and we'd have set up about two or three banks of these developing tanks. They'd be about easily a metre and a half deep. They'd hold about thirty litres of developer and chemicals, fixer. You could have a team of about twelve blokes… And in there you could hang thirty films at a time.”John Garrett

John commented that “the number of films we put through was enormous” and that the women working on the print machines were “worth their weight in gold” due to the huge amount of prints they processed each day. “It was a big, big job, but of course we were up against competition and competition was pretty fierce.”

From Peak to Closure

Responding to fierce competition, Kodak Australasia’s Burnley factory offered a fast same-day service, as well as a 24-hour service. Staff delivery drivers were an important part of this timely operation. They picked up unprocessed films from Kodak dealers, such as chemists, and dropped them off at the Burnley facility. After being developed and printed, the drivers delivered the finished photographs and negatives back to the dealers for customers to pick up. A garage near the Burnley facility was used to house the delivery vehicles.

With these quick same-day and 24-hour response times, working at Kodak’s Burnley factory could be challenging at times; work was highly manual and repetitive, and staff worked tirelessly to meet their daily targets.

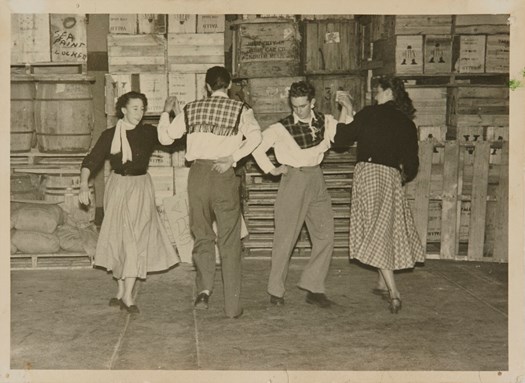

Despite this, however, Burnley employees were able to access various facilities, such as a staff canteen, as well as a range of recreational activities. In the 1950s, for example, workers organised a Double K Square Dance Club and used the Powder and Solutions store-room as a dance-floor. Max Myers, who worked as a plumber at Burnley, recalls:

"Oh yes, at lunch time we used to go square dancing... It was Pearl Cleaver, Marie, oh I can’t think of their names now. Two of the chemists. Myself. Another girl from the D & P. A couple from the D & P. Oh, we used to have a good time at lunchtime."Max Myers

In the 1960s, staff celebrated Christmases at the Burnley building and in the early 1970s there was a table-tennis table area tucked away, adjacent to the Powder and Solutions work space, where staff could take a break if they had time in their busy schedules.

In 1974, however, after over 20 years of bustling activity, Kodak’s Burnley factory ceased operations. The Powder and Solution Department was transferred to the bustling and large-scale Coburg factory at this time, taking up residence in Building 16 as the Photochemical Department, while the Black & White Photo Finishing Laboratory closed down permanently because a black and white processing and developing service was no longer seen as viable for the Kodak business.

Despite ceasing operations, the Burnley factory left behind a lasting legacy for Kodak Australasia, and for all the staff members that worked there over the years. In the words of Ed Woods, ex-Managing Director and long-time employee at Kodak, "the Burnley factory was a very, very important part of the [Kodak] business."