A Phenomenal Development

The Coburg Factory, 1961-2004

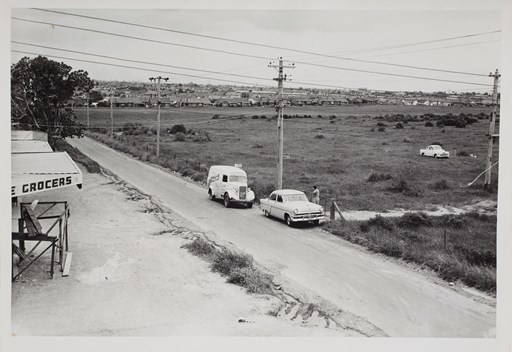

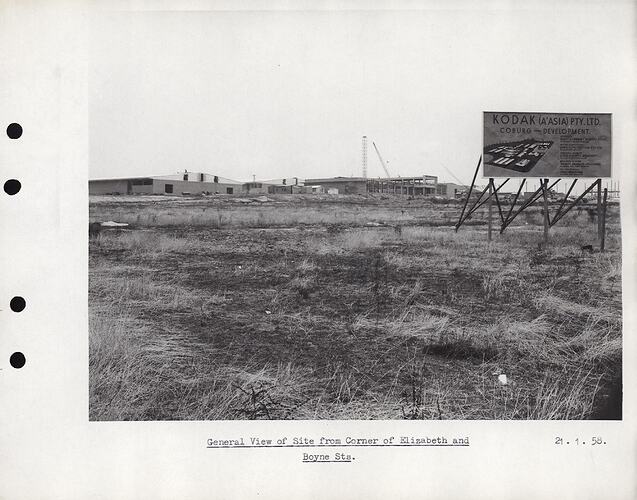

On a place inhabited by cows and farmland – and for many thousands of years before that, home to the Wurundjeri Woiwurrung people – the late 1950s saw a significant change begin to reshape the landscape in Coburg, Victoria. As large-scale industrial buildings were erected and heavy machinery was moved into position, a new and enormous facility began to emerge.

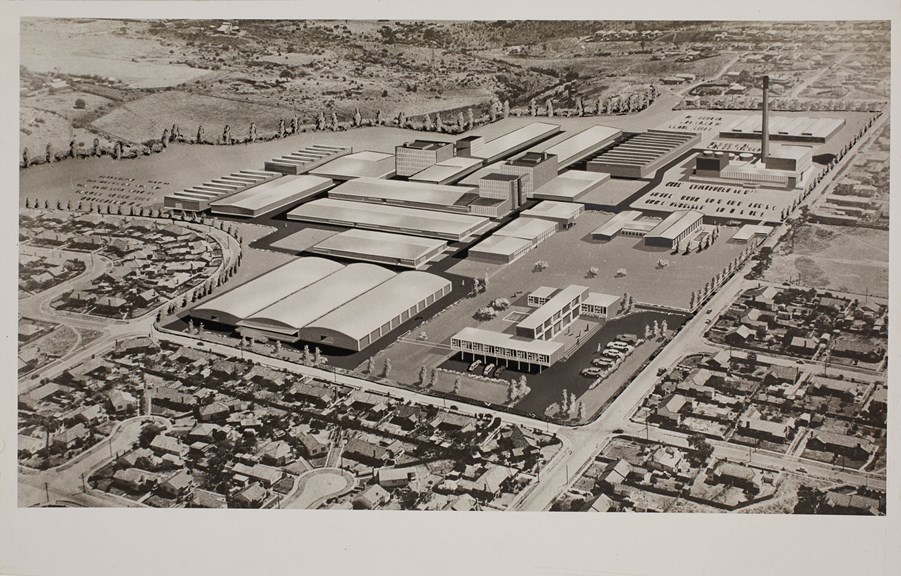

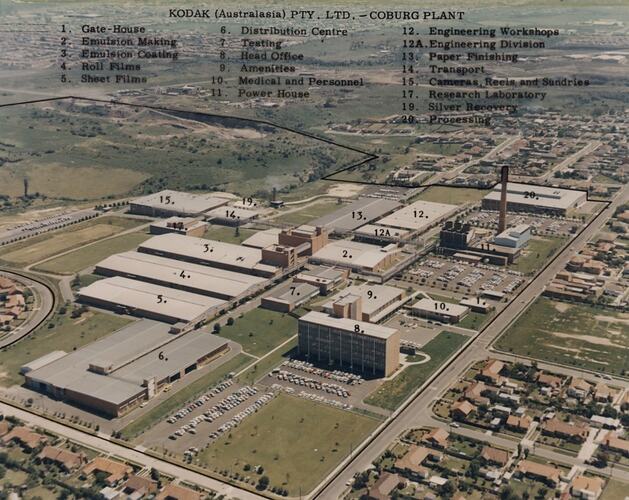

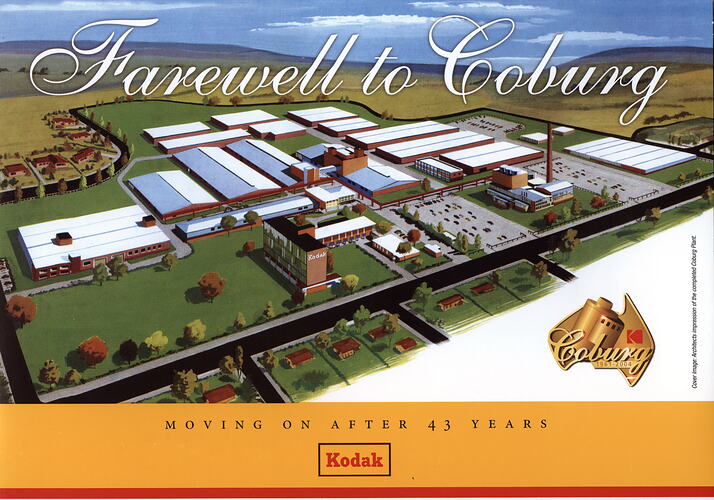

This is the story of Kodak Australasia’s Coburg factory – the largest factory in the City of Moreland that, from 1961-2004, employed many thousands of staff and played a significant role in the development of Australian manufacturing. A bustling facility spread over 21 buildings and inhabiting many acres of land, Kodak’s Coburg factory grew rapidly over the decades to become one of Melbourne’s most prominent and well-known manufacturing factories.

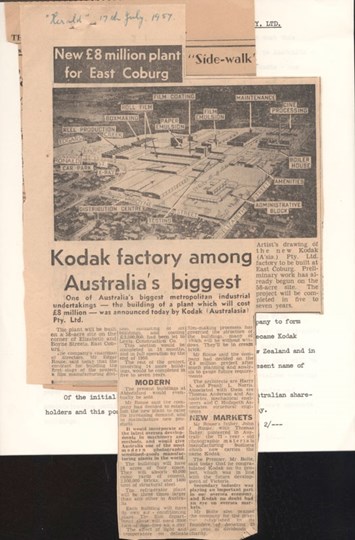

Although land was first earmarked and purchased in Coburg in 1943, it wasn’t until 1957 that Kodak officially announced the construction of the new factory. In a formal press conference held on 17 July 1957, Kodak Australasia Chairman of Directors Edgar Rouse delivered an enthusiastic speech, in which he stated that “the project is, we believe, one of the largest ever undertaken in the metropolitan area of any Australian city.”

“Our seven-acre Abbotsford site can no longer cope with the rapidly expanding Australian market. We have decided, therefore, to move to a new 58-acre site in East Coburg and to erect thereon a photographic materials manufacturing plant which we believe will be the most up to date in the world, and among the largest in terms of output ... We are proud, therefore, to be able to play a part in the surge of development that is so evident in Australia today."Edgar Rouse

In the same year, 1957, earthworks began in Coburg. Trish Lobb, who grew up overlooking the McKay farm and surroundings, remembers the shock and dust of early excavation works.

Digital Story – Trish Lobb, Construction Memories

Rapidly emerging from the landscape and enormous in scale, construction of the Coburg factory was delivered in stages, with departments transferring from Abbotsford as their new facilities became ready at Coburg. In 1959, the first building was occupied on the site. This was the Powerhouse, which was integral to providing services to the growing factory, and soon after this, X-Ray, Sheet Film, and Roll and Movie staff were transferred to Coburg.

By 1960, just two years after construction commenced, the first stage of the factory was completed, with the emulsion making facilities and coating track commissioned for operations, and paper finishing also ready to begin production. Building 9, which contained the amenities and canteen, was also in use.

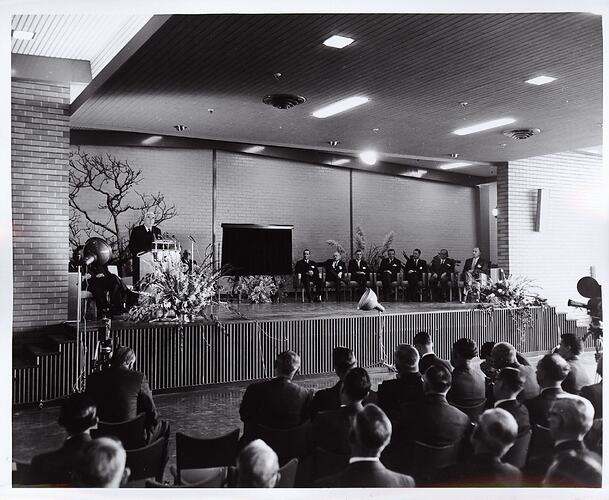

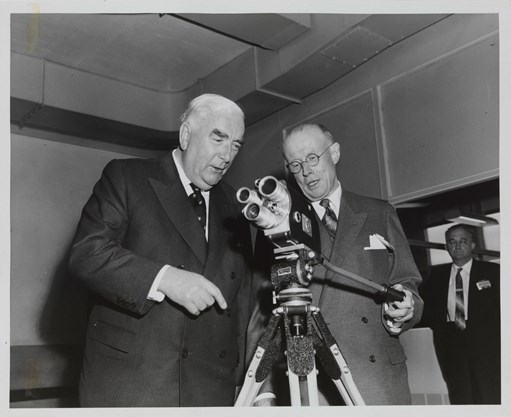

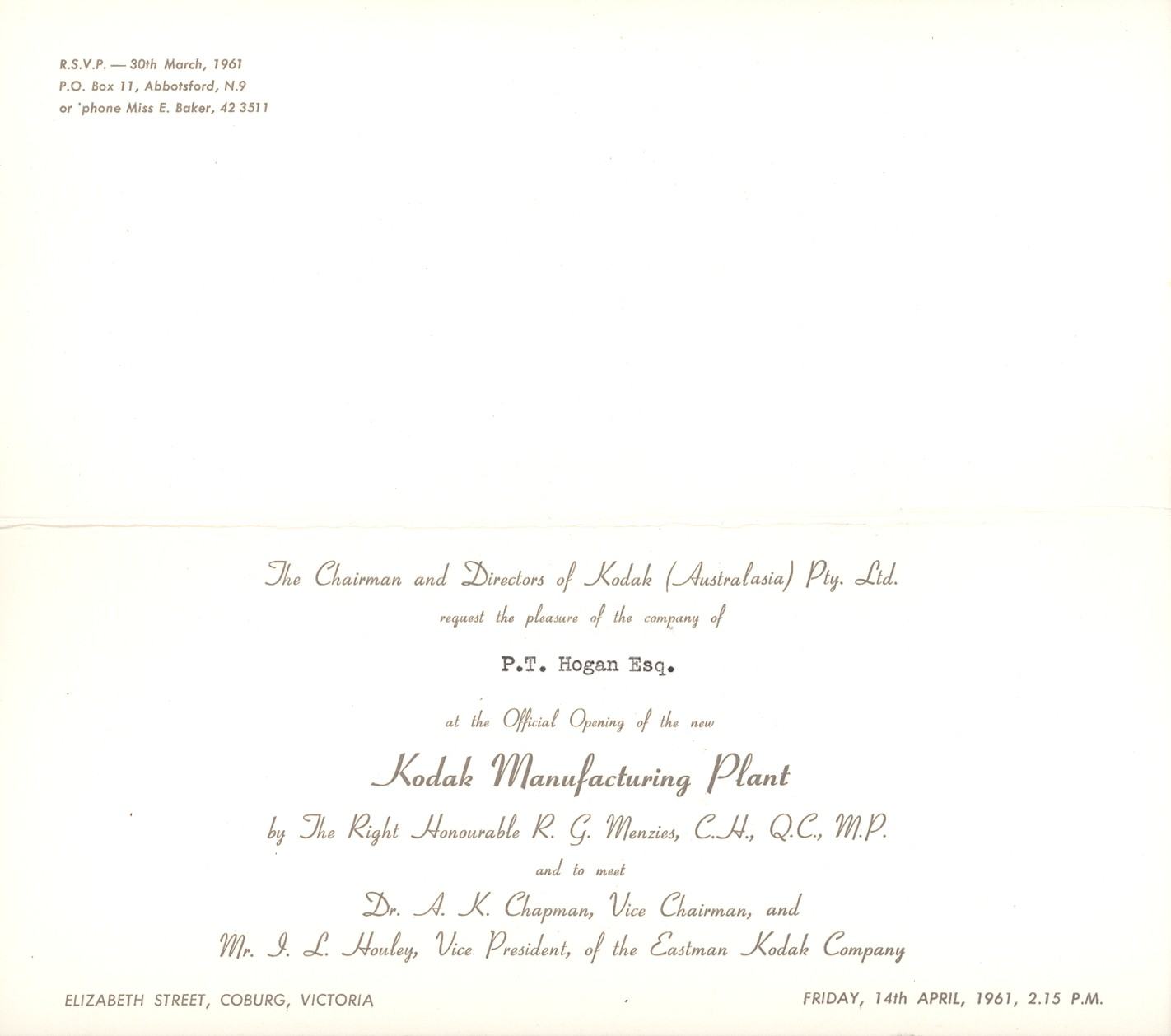

When Prime Minister Sir Robert Menzies visited Kodak Australasia’s newly constructed Coburg factory to officially celebrate its opening in 1961, he delivered the Official Opening speech, in which he declared:

"This is a phenomenal development, this magnificent site in this good setting, with a vista of the future that exhibits no small outlook on the future of Australia. I am delighted to be here. I would like to congratulate everybody who has anything to do with it, and I give myself the singular pleasure of declaring it open."Sir Robert Menzies

The fact that the Coburg factory was opened by the Prime Minister of Australia – and that the Prime Minister saw this factory as a “phenomenal development” playing a role in shaping “the future of Australia” – highlights just how important Kodak was in Australia’s manufacturing industry at the time. Big things were expected of Kodak’s Coburg factory, and even in those early years it was looked to as a beacon of Australian manufacturing progress, success and innovation.

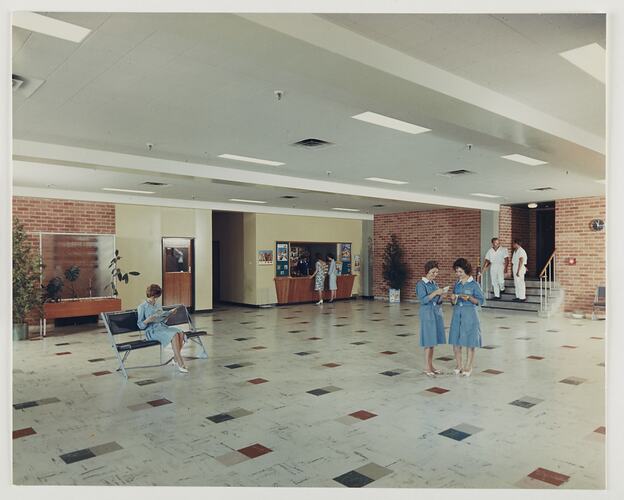

The opening event was hosted in Building 9, the Amenities Building, taking advantage of the canteen and theatrette. As well as the Prime Minister of Australia, attendees also included Dr. A Chapman, President of Eastman Kodak, the Governor of Pentridge, senior and longstanding staff from the Abbotsford and Burnley factories, the media, local Coburg councillors and headmasters from local schools. It was a significant and momentous event, heralding a new chapter in Kodak Australasia’s manufacturing history.

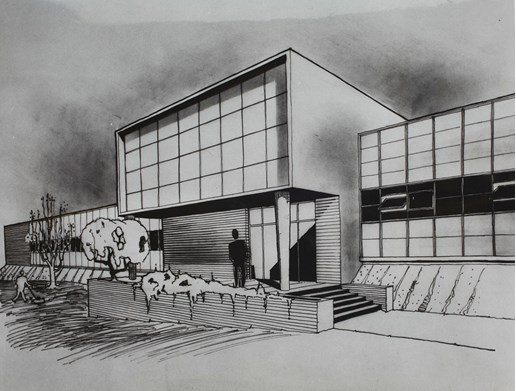

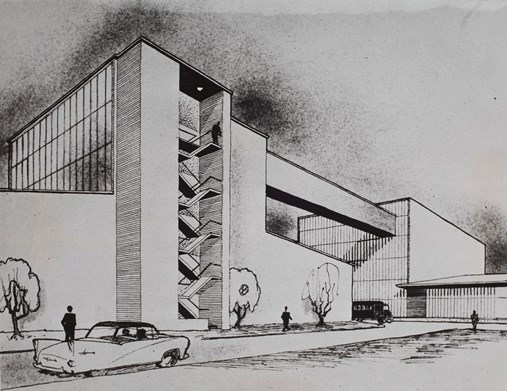

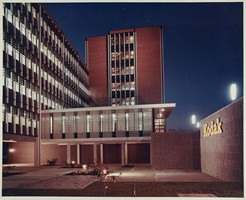

While the Coburg factory was immediately hailed a beacon of Australian manufacturing progress and technological advancement, it was also looked to as a testament to modernist architectural design. Architect Harry Norris of HA and FL Norris & Associates was appointed to design it, while Lewis Construction won the tender to build it. The design was apparently modelled off Eastman Kodak plans, designed to suit the North American climate, but modified for Australian conditions.

Grounded in modernist design principles, with sweeping straight lines, elegant detailing and high-quality finishes, the building attracted great fanfare and interest, and during the 1960s many proponents of modernism came to view, document and celebrate the building. Melbourne photographers Wolfgang Sievers and Mark Strizic – now renowned for their modernist photography – were commissioned to photograph and visually record the finished complex.

The importance of the Coburg factory building to Australia’s collective history, and to Australian modernist design, is well articulated by the Victorian Heritage Register:

"It is a fine example of an architect-designed mid-twentieth century factory complex in a landscaped setting … a fine, intact and varied example of the work of Harry A and Frank L Norris & Associates, a noted and prolific Melbourne firm of commercial architects, whose post-war work demonstrates a highly personal strain of International modernism."Victorian Heritage Register

Gallery – Wolfgang Sievers and Mark Strizic

While most of the factory’s production, office and amenity buildings were completed during the 1960s, the development of the Kodak site continued right up until the end of the 1970s, with some significant modifications occurring up to the 1990s to improve production efficiencies.

At full completion the Coburg factory totaled a whopping 21 buildings. Each building was fitted out with offices, meeting rooms, storage rooms, trade workshops, amenities such as lunchrooms, male and female locker rooms, toilets and showers.

As the Coburg factory rapidly evolved, its predecessors in Abbotsford and Burnley began to wind down and eventually cease operations. In 1966 the longstanding Abbotsford factory, which was now over 80 years old, was vacated and put on the market, selling in January 1967. Before its sale, some symbolic elements of the old factory were transferred to the new Coburg site, including bluestone from Thomas Baker’s former home, which was constructed into a retaining bluestone wall in Coburg, and an acorn from a tree at the Abbotsford site, which was planted in Coburg in 1961.

In 1973-74 the Burnley factory also ceased operations, with staff from the Powder and Solutions Department transferring to Building 16 at Coburg. By this point in time, the Coburg factory had become Kodak Australasia’s beating heart – the central manufacturing hub producing a wide range of products including Ektacolor Paper (1960s-2004), Kodacolor film (1960s-1996), X-Ray (early 1960s-early 1990s), Graphics (1960s-mid-1980s) and Black and White Papers (1960s-late 1970s).

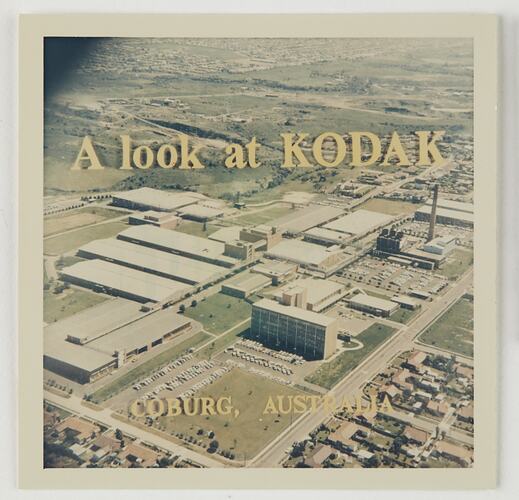

A Look at Kodak, Coburg, Australia

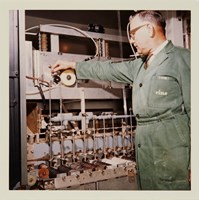

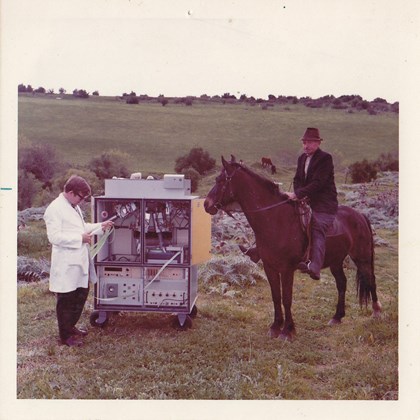

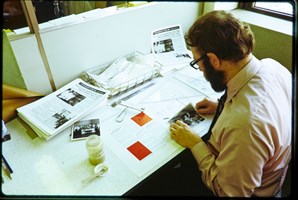

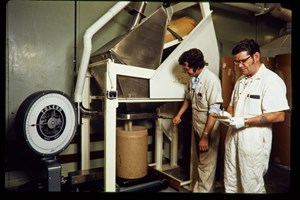

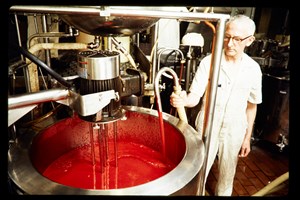

The following slides – taken from a 1960s Kodak presentation titled “A Look at Kodak Coburg Australia” and put together by the Photo Information Services Department – provide a window into working life, machinery and operations at Coburg in that first decade of manufacturing and production. This is just a small sample of the many 1000s of slides contained within Museums Victoria’s Kodak Heritage Collection.

As Coburg continued to expand and grow into the 1970s during a period of significant manufacturing and distribution for Kodak Australasia, this expansion came at a cost for some, and especially for the McKay family farm.

By the mid-1970s, the farm had well and truly been encroached upon by both industry and housing, and the factory and farm were so close that the farmer and factory worker sometimes crossed paths. In 1977, as Kodak made plans for the construction of a new Distribution Centre, Alan McKay received a letter notifying him that Kodak wished to terminate his tenancy. Alan’s wife Edith recounted the family sentiments at the time in a letter that she wrote to Alan’s Aunt, Myrtle Irene:

"I hope you are sitting down as you read these few lines. Here it is, Kodak are moving in December. We have to get out by 30th November, we have to pull down the sheds, barn and the lot, so we have had a hectic time."Edith McKay

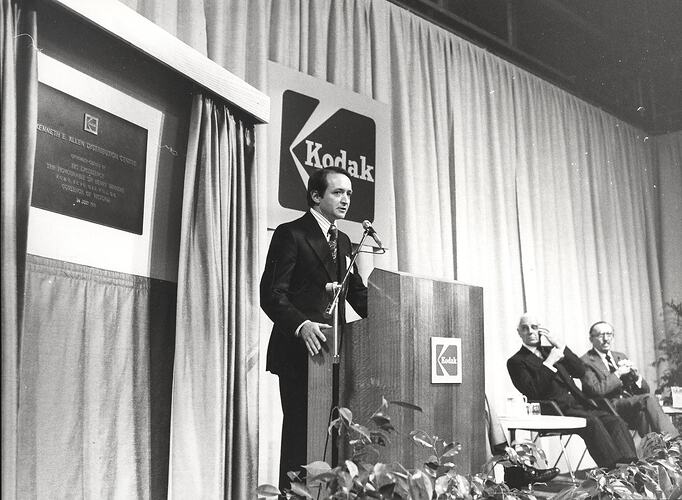

By 1979 the McKay family farm had been replaced by a large new Distribution Centre. Named the Kenneth Allen Distribution Centre after a Managing Director who had sadly passed away while incumbent in his role, the centre was officially opened in 1979 by the Victorian Governor Sir Henry Winneke, with a speech from one of Coburg’s long-time Kodak staffers Dr Peter Harvey.

The gradual erosion of the McKay’s family farm as Kodak took up land for the factory during the 1950s-1970s was a classic example of the shift in the identity of Coburg in the mid-20th century. Signifying an end of agricultural enterprise in Coburg, it ushered in a new era of industrial and manufacturing expansion and it wasn’t long before the Coburg factory had become the largest factory in the City of Moreland.

With its 21 buildings spread across many acres of land, Kodak employed a wide and varied range of staff over the decades, including manufacturers, managers, research scientists, secretaries, gardeners, canteen cooks, cleaners, film processing staff, marketing specialists, design engineers, and that’s just to name a few. Factory staff numbers peaked at around 2,300 in the early 1970s, 1,500 in the 1980s and were approximately 1000 when the closure of manufacturing was announced in September 2004.

Coburg Factory Tour

The following footage, taken in the 1960s, provides a window into the bustling Coburg factory and the wide array of work activities that were undertaken by staff across the site.

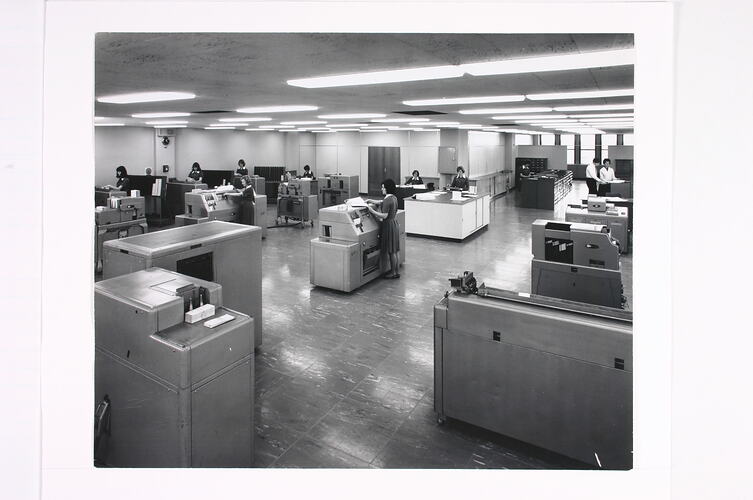

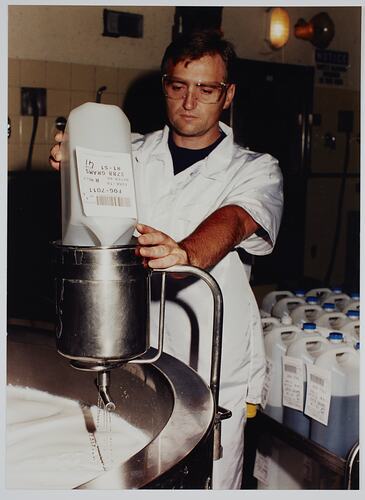

The depth and breadth of work being undertaken at Coburg was expansive and diverse, with each building containing widely varied areas of expertise and focus. While marketing staff were busy developing advertisements and sales pitches in the Head Office at Building 8, emulsion workers were mixing chemicals in Building 2 and Film Finishers were slitting, spooling and packing in Building 4. Cooks prepared meals for the thousands of staff members in the Amenities Building kitchen, while educational classes, training and research were underway in the Research Labs in Building 17. These are just some of the many activities that were going on in a day’s work at Coburg. View a detailed list of all the building functions here.

The sheer size and scale of Coburg’s machinery itself was also enormous. The Powerhouse building, (Building 11), for example, consisted of an integrated Machinery Hall with north and south annexes, a Boiler Hall, evaporative water cooling towers and a towering 62 metre chimney stack, as well as oil bunkers, a tank farm and office/amenities block. Doug Howden, who oversaw the Powerhouse for over a decade through the 1990s up until Coburg’s closure in 2004, recalls that the Powerhouse was “the heart of the place”:

"It was state of the art, it was good quality … generally people don’t want to go near a Powerhouse because it’s a big, aggressive thing, it makes a lot of noise. But because everything is high pressure, it’s really well made, really well-designed and a pleasure to work on."Doug Howden

Doug’s reflection on the ‘state of the art” equipment at Coburg is a reflection that could arguably be applied across all the buildings at Coburg. Modern, highly specialised and made to the best industry standards of the time, the Coburg site was an impressive feat of engineering that grew to have an international standing.

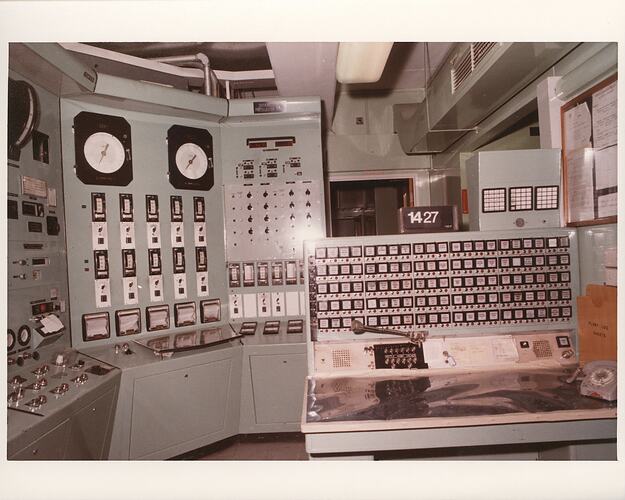

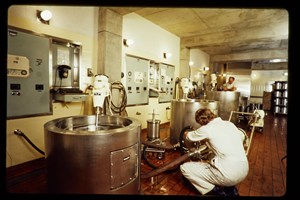

Built in the late 1950s-early 1960s, in the era of the Space Race and Cold War, stepping inside the control room for the Emulsion Coating Machine must have felt like stepping into a spaceship. With highly technical buttons and control systems, Coburg’s emulsion facilities – located in Buildings 2 and 3 – included “kettles”, large film rolls and a coating machine and was the only facility of its kind in the Southern Hemisphere. The coating machine itself was so large that it occupied almost an entire room in Building 3.

Some of the thousands of staff at Coburg included those who had started their careers at Abbotsford, and in oral history interviews for the Kodak Heritage Collection, many have commented on the novelty of suddenly working with such new, shiny and modern equipment. Two such staff members were Michael and Lucy Mikedis, who as European migrants, were part of a post-World War II cohort of migrants working at Kodak.

Michael and Lucy Mikedis

There were also lots of new staff with no experience in the photographic industry, including Yvonne Cameron, who lived on the northern boundary of the factory and watched the Coburg factory develop from the ground up.

Yvonne Cameron

Colour print Processing

One of the major products produced at the Coburg factory was Kodacolor film, and Coburg also processed film via the Colour Print Processing Department. The following scenes provide a window into working life in the film department in 1964.

Working Life, 1970s

A common theme uniting interviews with ex-Coburg staff members is the sense that Kodak’s Coburg factory offered relatively progressive employment conditions. Staff have often commented on feeling like part of a ‘Kodak family’ and in turn, many went on to have long and loyal careers at Coburg.

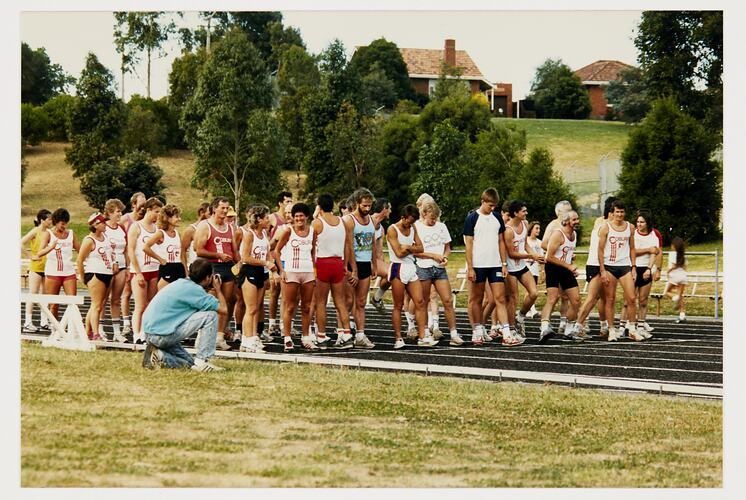

Kodak was known for offering a range of staff benefits, including a wage-based bonus system, an on-site medical centre that offered full medical services including x-ray and physiotherapy, a sporting complex called the ‘Fit Pit’ that was opened in 1985 and a wide range of other recreational activities such as marathons, sporting competitions, carnivals and, loved by many, the Kodak Camera Club.

Coburg also hosted an annual Kodak Children’s Christmas Party, which was a widely anticipated social event featuring jumping castles, merry-go-rounds and in one year, 1350 children in attendance! News about Kodak staff activities, such as these Christmas parties, was circulated in the staff newsletter, the Kodakery, later known as Kodak News.

Social and recreational activities were, for many staff, a significant part of working life at the Coburg facility. Among the many activities enjoyed by staff were golfing, athletics, balls and dances, exercise groups and, on a day-to-day basis, thriving conversations and friendships formed in the Coburg factory’s central meeting place – the Amenities Building canteen.

In oral history interviews with Museums Victoria, many ex-employees have shared fond memories of their time with Kodak. Greg McKibbin – who began as a marketing trainee with Kodak in 1964 and stayed on until after the 2004 closure as Managing Director up until 2009 – was one such long-time employee that had fond memories of working for Kodak, reflecting that “it was like a big family.”

"I didn’t have another job. I spent all my time at Kodak. And I know when I met people out in the business world there was a very strong reputation in the 90s and 2000s of what Kodak did for their staff and the culture of the company … It was a fantastic company. I really can’t think of one morning I didn’t want to get up and go to work."Greg McKibbon

The factory was probably at its peak in the 1970s, with a busy production schedule. Yet in 1976, following a period of global recession and economic stagnation, a product rationalisation was held. And by the 1980s-1990s there were further reductions in products made at Coburg, and ongoing job losses.

In the early 1980s the Kodak plant at Coburg made and coated with photographic emulsion twenty-four hours a day, seven days a week. Brian Flynn, who was an emulsion worker at Coburg in the 1980s up until Kodak closed in 2004, recalled that “they couldn’t make enough of it.”

But, by the mid-1980s as global economic pressures started to make an impact, rosters were altered to require workers to do 12-hour shifts, instead of 8-hour shifts. Brian “found it extremely hard towards the end, doing twelve hours” in a job that required intense concentration and focus.

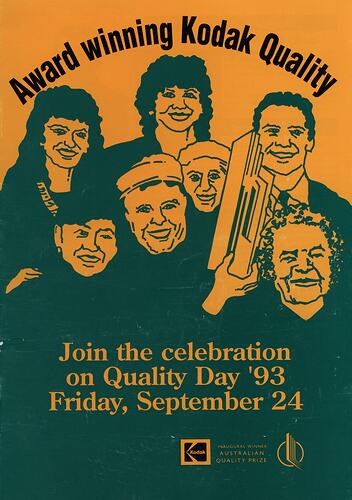

In the attempt to be more cost effective in the world market, in 1983 Kodak undertook a Quality program – aimed at increasing efficiencies and reducing waste – and in 1988 and 1992 won the inaugural Australian Quality Award.

The 1980s-1990s also saw a wide range of other successful initiatives arise, including Kodak Health, which utilised advanced digital imaging technologies and was aimed at assisting hospitals to transition to digital imaging. The Coburg plant had been a leader in medical imaging and X-Ray technologies since it opened in the early 1960s, and in the 1990s Kodak Health successfully evolved from analogue to digital technologies and began to expand operations into the Asia Pacific region. Elizabeth Delahunty, who worked at Coburg from 1982-2008, was General Manager of Kodak Health and recalls:

"Through that period of time across Asia Pacific, which included Australia and New Zealand, we tripled the size of that business and we also significantly increased the profits of that business. Kodak Health, I always felt, was a jewel in the crown for Kodak... It had successfully made the transition to digital. We still had some analogue products, but we were well on the path to digital. We were competing successfully in the market."Elizabeth Delahunty

During the 1990s-early 2000s, the Coburg Facility also expanded its film export operations, with film being produced and packaged specifically for the Asia Pacific market. Yet, despite their success over a period of years, major initiatives such as the Australian Quality Award, Kodak Health and specialised film exporting were not enough to halt the continued decline of revenue, staffing and production output at Coburg.

As digital imaging transformed the world of photography in the 1990s, this shift in technology caused a huge decline in the demand for film. Many staff, such as emulsion worker Brian Flynn, could see the writing on the wall:

"The collapse of the industry? Yeah. If you read any magazine, you knew the digital camera was coming."Brian Flynn

Despite attempts to stem the decline, outputs shrank, profits dried up and mass redundancies took place. By the early 2000s, there were less than 1,000 staff remaining, and just a few products coming off the local production lines.

The 2004 Closure

When Kodak opened in 1961 and the then Prime Minister referred to it as a “phenomenal development” in an era of optimism and economic growth, it was unimaginable that this modern new manufacturing facility would ever shut down. However, in 2004, with the world now firmly in the grips of a digital imaging revolution, Kodak Australasia’s film reliant manufacturing business came to an end.

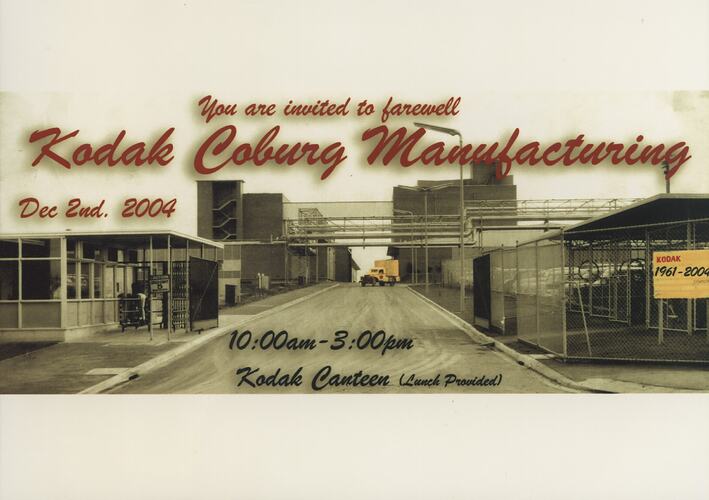

The closure, for many, felt very sudden. It was announced to staff on 16 September 2004, with John Allen, chairman of Kodak Australasia at the time, making an official statement:

"It is with regret that I announce the closure of the Coburg manufacturing plant … These closures have been caused by the fundamental change in consumer behaviour driven by the increasing popularity of digital photography in Australia and worldwide."John Allen

For many, the closure came as a devastating loss, and especially hard-hitting given that the move to shut down operations had happened so suddenly, with just two months’ notice. On 26 November 2004, with great sadness, staff undertook the last ever film production run, leaving most of its work force out of a job.

Digital Story – Recollections of the Closure

The following reflections were captured via oral history interviews with ex-staff members who experienced the 2004 closure.

While Kodak Australasia’s Coburg factory closed in 2004 and permanently shut its doors, the company has survived as a much smaller entity that functions largely as an import and distribution subsidiary of Eastman Kodak. It continues to be based in Melbourne. The Coburg factory, and all its original buildings, have all been demolished, with a new era of housing development, known as Coburg Hill, reshaping the landscape once again.

Despite the sadness and loss felt by many when the buildings were demolished, Kodak’s Coburg factory continues to live on in the memories and hearts of the many thousands of people that shaped its legacy.

*This story is adapted from a talk that was given in 2021 to the Coburg Historical Society by Senior Curator of the Kodak Heritage Collection Fiona Kinsey. You can view it here.